Friction Springs for Earthquake Protection

If buildings are shaken by earthquakes this can lead to cracks, instabilities in the support structure and in worst case szenarios to the collapse of the building. To efficiently absorb the enormous forces and thereby protect both, person and material, nowadays sophisticated technologies are available.

Not all damages that a great earthquake will cause can be avoided. However, with Friction Springs there is a very high probability, that the building withstands an earthquake – like those in Christchurch/NZ in 2010 and 2011 – and is still operational and habitable.

Friction Springs in Real Life

There is already a number of large buildings in New Zealand which are equipped with Friction Springs and tested in reality. An example: The Te Puni Village student residence in Wellington. It was already completed when the earthquake on 21st July 2013 occurred with a magnitude of 6.5 and aftershocks with a magnitude of 5.8 on the moment magnitude scale (MMS).

The aim was to balance the soil acceleration in case of an earthquake. The Friction Springs here work in conjunction with a special type of connection between the supports and traverses of the steel supporting frame of the building. These are carried out as sliding hinge joints (SHJ) and have the task to absorb energy and give the building flexibility. This alone means, that a part of the energy will be absorbed, but the building itself will not have the original position after the earthquake, but rather stand at an angle.

At this point the Friction Spring is employed: It creates the "Self Centering Sliding Hinge Joint". That means, the Friction Spring additionally extracts a major portion of the energy input in conjunction with the sliding hinge joints and moves back the building into its initial position. The building resisted the earthquake without significant damages. The innovative concept was awarded by the British Institution of Structural Engineers with the 'Healthcare-Structure-Award'.

Advantages of a Friction Spring

Durability

Friction Springs are designed in a way that they can run through many cycles and are reusable. In case one ring of the spring breaks, you only lose a part of the spring travel and the stiffness will slightly increase – but the it will continue to work. For comparison: If a coil spring breaks this means a total failure of the function and you have no protection anymore.

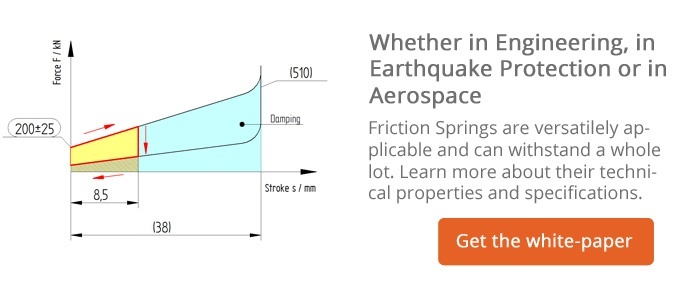

Damping

With the grease F-S1 two thirds of the introduced energy will be absorbed. In case you require less damping, we can easily create a customized solution as per your requirements. With this a reduced damping of up to appr. one third of the introduced energy can be achieved. This simple solution can modify the characteristics of the Friction Spring. In certain seismic applications a higher force is required when unloading the Friction Spring to return the building structure into a vertical position.

Fire and High Temperatures

Friction Springs are made of a special spring steel and lubricated with grease. If a fire or high temperatures occurs, it will withstand these specific environmental conditions – contrary to rubber, elastomers or hydraulic dampers: These would be destroyed by fires. The Friction Spring, in contrast, only has to be relubricated.

Reset Force

For each application you can find the best reset force of the spring. You can achieve the required result e.g. through the use of a different grease, the modification of the thickness of the rings or the modification of the cone angle. This is not possible with conventional spring types.

Reusability

Friction Springs can be reused after a seismic event. They are designed to run through many cycles while retaining their positive characteristics. Moreover they are also maintenance-free. This saves you time and costs.

Reaction Speed

Friction Springs react faster to induced forces than all other spring types.

Mounting Space

Friction Springs can absorb very high forces in relation to their diameter.

Friction Springs will increasingly be a part of the future constructions for the protection of residential buildings and high voltage circuit breakers (for electrical energy transmission) against earthquakes. In one of our last articles you can read how a Friction Spring works. Download our Whitepaper for more technical information or contact our experts for Damping Technology.

Source: Clifton, C. et al., "Experimental Study of Full-Scale Self-Centering Sliding Hinge Joint Connections with Friction Ring Springs", Journal of Earthquake Engineering, 17:972-997, 2013

Comment