Torque Support in Practice: A High-Torque Application with RINGFEDER®

In drive systems exposed to high torques, uncontrolled reaction forces can lead to unwanted movement, increased wear, and reduced service life. Torque supports are, therefore, a critical design element in many industrial applications. This article examines their role using a practical application example and highlights the technical requirements placed on torque supports in heavy-duty drive systems.

Torque Support – Function and Principle

A torque support has the task of absorbing differential torques and transferring them to a supporting structure. This can be the housing or frame of the corresponding machine. This prevents the housing or motor itself from rotating. They are also used to fix components in place, limit movement, and reduce vibrations.

A simple example of this is the coaster brake on a bicycle.

Picture 1: Torque support for bicycle coaster brakes

Application Example: Drum Drive System

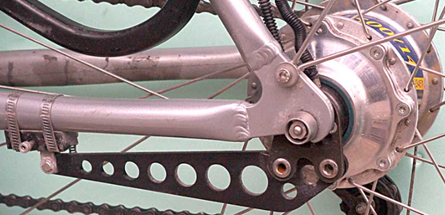

In an application from Getriebebau Nossen, the push-pull unit in this gearbox acts as a spring-damper element and ensures symmetrical load distribution on the output wheel of a drum drive. It compensates for load peaks and dampens vibrations to protect the drive components. This is a decisive factor for durability and operational reliability.

A continuous and reliable output torque of approximately 1,000,000 Nm is delivered at speeds of up to 0.6 rpm.

These dimensions illustrate the demands placed on such systems in areas such as raw material extraction or steel production.

Technical Requirements

The most important requirements were:

-

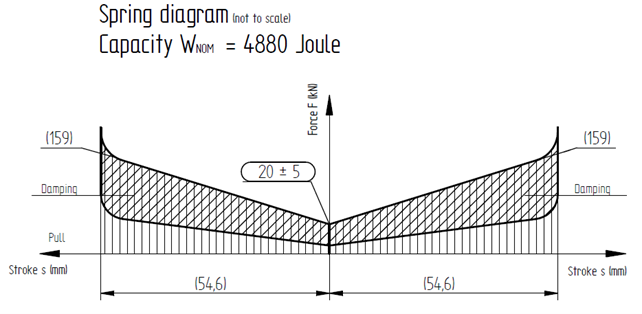

Absorption of a maximum operating force of 116 kN

-

Spring travel of 34 mm

-

Absorption of a maximum overload of 2 × Fmax in an emergency

-

Ambient temperature range: –10 °C to +45 °C

-

Damping between 30% and 40%

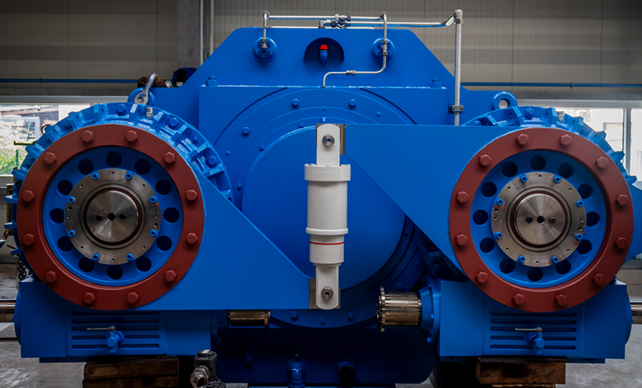

RINGFEDER® Design and Configuration

To achieve these values, a type 12400 spring with 24 elements was used in the calculations. RINGFEDER® special grease F-M12 was used to achieve the required damping value in relation to the temperature range.

The length over the centre of the fastening lugs was set at 650 mm. It was important to ensure that there was no collision between the outer contour of the housing and the torque support when the unit was compressed.

Picture 2: RINGFEDER® push-pull unit in torque support from Getriebebau Nossen

Picture 3: Force-displacement diagram of the RINGFEDER® push-pull unit used

Conclusion

This application demonstrates the use of a torque support to absorb differential torques, damp vibrations and protect drive components under extreme operating conditions. The described configuration enables reliable torque transmission and contributes to durability and operational reliability in heavy-duty industrial applications.

Comment