Alternative design of the steel framework roof of the departure hall at Athens Airport using SAP2000® and Push-Pull Units with RINGFEDER® Friction Springs

In our last Blogpost, we presented, how you can implement RINGFEDER® Friction Springs into SAP2000® to protect your building structure efficiently. This practical example shows their advantages compared to a conventional solution.

Athens Airport is the international airport of the Greek capital city, which was opened in 2001. As the largest Greek airport, it reached a passenger volume of 28,2 million passengers. The roof of the departure hall spans 60 m and is protected against earthquakes. The horizontal earthquakes are dissipated by complex friction bearings in combination with viscose damping elements. As part of a case study by the University of Kaiserslautern, the alternative use of our Push-Pull Unit with RINGFEDER® Friction Springs instead of the complicated bearings was investigated. The results show that the alternative approach with friction springs reduces the seismic loads by the same order of magnitude but offers significant advantages in terms of maintenance and recentering after an earthquake event. The structure must withstand high-ground accelerations of 0,16 g. The biggest problem to solve is the 60 m x 60 m long-span roof. Caused by the high accelerations, the nearby structures are facing high loads, that need to be dissipated. The roof is supported by four different reinforced concrete structures, which also move differently in an earthquake. A stiff connection between the steel framework roof and the concrete structures would lead to large forces. For this reason, friction bearings and additional viscous damping elements were chosen. Shortly after the installation of the dampers in 1999, an earthquake occurred, causing considerable damage to buildings in parts of Athens. Athens Airport remained undamaged.

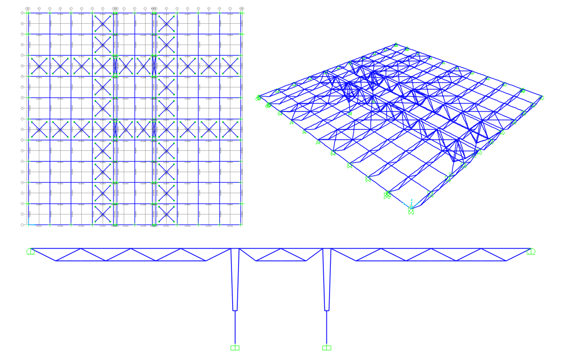

The Institute of Structural Analysis and Dynamics at the RPTU Kaiserslautern investigated the structure of the roof in terms of the use of Push-Pull Units with RINGFEDER® Friction Springs. The function of the friction springs was modelled and analysed using non-linear time history calculations on an FE model. The results were then compared with those of the hydraulic dampers and a steel structure without additional dampers. The numerical model confirms that if no dampers are used, very high earthquake loads will occur, which cannot be absorbed without additional reinforcements.

Picture 2: Calculation model Departure Hall Athens Airport SAP2000®

The time history calculations show that forces of 322 kN would result at the outer supports. However, if the system is equipped with hydraulic dampers or Push-Pull Units, the internal forces are reduced to such a degree that no damage is to be expected. The external support forces are reduced to 81 kN by the Push-Pull Unit.

Picture 3: Currently used hydraulic dampers

For the calculation, we used RINGFEDER® Friction Springs with a maximum force of 83 kN and 30 elements. With a preload force of 30% and a maximum spring travel of 37,8 mm, we result in an utilization of 94%. The damping effect is fully effective through the use of Push-Pull Units. The design of the friction spring is based on two parameters. The loads that are applied by the friction spring at the corresponding points in the steel structure or supports and the permissible deformations. Both values are adjusted flexibly by the stiffness and size of the friction spring and can be fully customised to the requirements of the structure.

The numerical comparison between conventional hydraulic dampers and the Push-Pull Unit with friction springs shows that both systems are generally suitable for establishing the load-bearing capacity of Athens Airport for an earthquake load. However, the Push-Pull Units have several design advantages. They are maintenance-free, no hazardous oil can escape, and they provide automatic re-centring after an earthquake event to avoid permanent deformation and therefore expensive damage. They behave well in the event of fire and are extremely robust. Even if a ring in a friction spring assembly breaks the Unit will remain in function with minimally reduced spring travel. Push-pull units or dampers with RINGFEDER® friction springs are a highly suitable solution for earthquake designs.

Comment