Friction Springs Provide Damping For Mechanical Couplers

As you probably know, compact friction springs improve damping performance and give off high kinetic energy in a wide range of mechanical systems. Wabtec Corporation experienced this first-hand when they used our friction springs in their mechanical couplers for trains.

In this post, we’ll show you the role our friction springs play in connecting train cars.

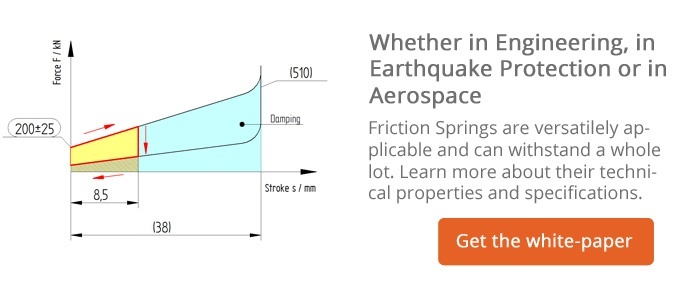

Friction springs absorb and dissipate energy. Mainly used in applications requiring kinetic energy absorption, our friction springs provide Wabtec mechanical couplers with the damping they need. Some benefits include:

- High spring work combined with low weight and volume.

- Overload-safety in blocked position.

- Independence of loading rate.

- A diagram independent of temperature.

- Maintenance-free operation.

Another way our frictions springs enhance Wabtec systems is by absorbing and dissipating energy. When the first car approaches and connects with the second one, there’s a compression in the mechanical coupler and a reactive force that springs the cars apart from each other. Our friction springs relieve this tension.

Better than hard rubber and nylon. While friction springs are the strongest option for these mechanical couplers, there are several other options on the market. Hard rubber or nylon donuts can be mated to a flange or ring. Individually, these have damping properties. But when stacked together, the dimensional envelopes and the amount of force in tension needs to be managed. Our friction springs are a longer-lasting technology with high quality performance and reliability.

Wabtec, formerly Westinghouse Air & Brake, makes mechanical couplers that engage opposing hooks and cam links on trains. As the trains come together, electric portions connect train lines for various electrical circuits including propulsion, braking, door operating and diagnostics.

Comment