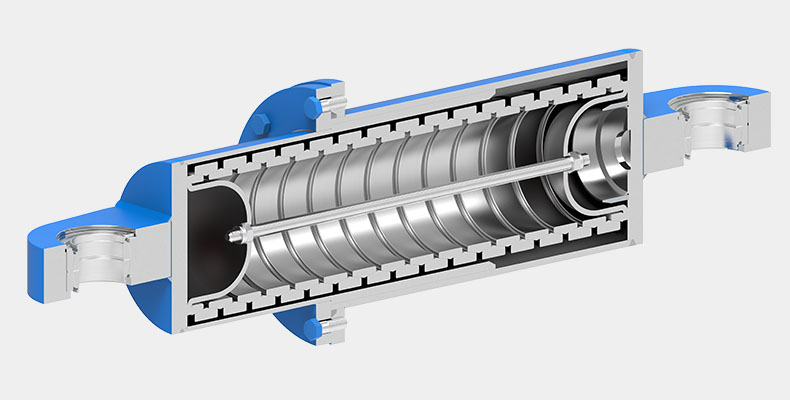

Endstops for Hot-rolled coils: RINGFEDER® Friction Springs Optimize the Coilbox at ArcelorMittal Eisenhüttenstadt

The automotive industry punches and forms car body parts from sheet steel, which they receive from rolling mills in the form of steel coils. They are hot-rolled to the finished dimensions required by the customer.

At ArcelorMittal in Eisenhüttenstadt, slabs of 225 mm thickness up to 12 m long are processed. The plant there is designed for hot-rolled widths of 600 to 1650 mm, whereby the thickness that can be produced is 1.5 to 13 mm. This also allows them to be used directly at temperatures up to 900 °C. This reduces fuel consumption and, therefore, emissions and increases the performance of the rolling mill by up to 50 %. The hot-rolled coils produced have a maximum weight of up to 34 tonnes.

Image 1: ArcelorMittal Eisenhüttenstadt - Steel Coil Production

The distance between the centerline of the beam furnace at the beginning of the rolling mill and the reel where the finished steel coils are rolled up is only 311 m. This is achieved by the use of a so-called Coilbox. It reduced the needed space for the machine by 60 m.

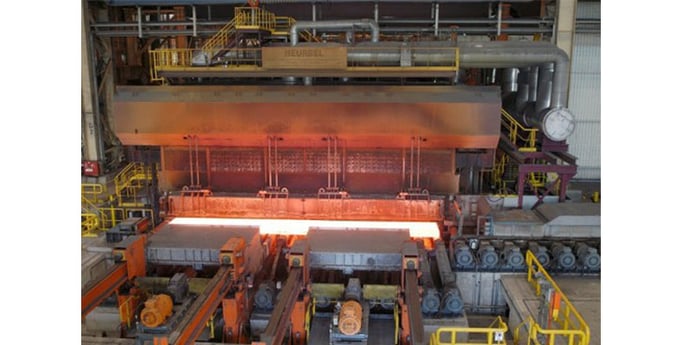

Image 2: RINGFEDER® Friction Spring Buffer in cross-sectional view.

A retaining roll is installed on the driver unit. When the coil unwinds, it is pressed against the retaining roller. Two dampers on both sides of the driver unit are required to slow down the coil. On the one hand, they are intended to absorb the energy that occurs to protect the system against damage and, on the other hand, to work reliably under the given harsh conditions. The system is only stopped at maintenance intervals.

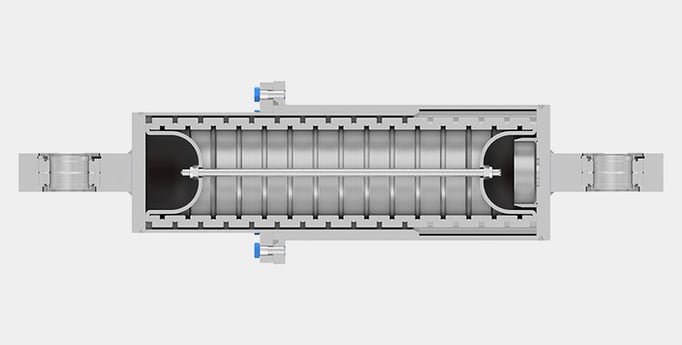

Image 3: Buffer connection can be customized according to customer specifications.

The damping concept was also revised as part of a project to redesign the coil box. The previous solution, which included a helical compression spring, was dropped and replaced by buffers with RINGFEDER® friction springs. The requirement is to absorb a maximum energy of 34,000 joules per buffer over spring travel of 100 mm. A preload force of 100 kN results in an operating force of 583 kN. The installation length over the centre of the eye is 978.5 mm. This resulted in the use of the special ring type 19700.

.png?width=682&height=362&name=MicrosoftTeams-image%20(3).png)

Image 4: Force-Stroke Diagram

Due to the large moving masses and the challenging conditions, RINGFEDER® friction spring products are ideal for use in the steel industry. Whether as an end stop or overload protection, the applications are manifold. Talk to us!

Comment