Market Talk 2/19 - An end to back pain, Smart Maintenance, how VW promotes the industrial cloud with Amazon and the tech trends of tomorrow

Typically, engineers focus on the smallest of details. From time to time, however, it is worth taking a look at the big picture – or even beyond it. What are the concerns of the market? What is being talked about and above all: where does the journey lead to? Here is our overview.

AI-supported orthosis prevents backaches

In a recent survey, 57 % of interviewed employees stated that they went to work despite suffering from back pain. At the same time, the number of sick leaves for employees who are exposed to heavy physical strain at their workplace every day is increasing. But how can employees – from industrial welders to warehouse workers – be relieved from physical strain and how can backaches actively be prevented?

An innovative approach is pursued with the ErgoJack developed by the Berlin-based Fraunhofer IPK. Whereas common exoskeletons still permit unergonomic movements, the AI-supported real time analysis of the ErgoJack recognizes movements that are injurious to health. This is how it works: The motion sensors located on the shoulder, the back and thighs compare pre-learned movement patterns with the movement actually performed and analyze them in real time. The wearer immediately receives feedback by means of a vibration alarm if his or her movements are harmful to the back.

Deloitte looks beyond the digital frontier

The capabilities of AI-supported software have most recently been demonstrated by the efforts of Netflix: detecting illegally shared accounts for the video streaming provider by using Machine Learning. It is hence hardly surprising that Artificial Intelligence is one of the core technology trends for the visions of the future in the 10th Annual Tech Trends Report of Deloitte. To put it in a nutshell, the report deems the potential of digitalization as still far from being exhausted.

Even more: The high maturity level of artificial intelligence not only serves to streamline processes in future, but it is supposed to actively contribute to the corporate results as a turnover driver. So, a wonderful new world that will make the human being increasingly superfluous? At least, this is what can be read between the lines.

However, the key message of the report is straightforward: The trend toward an increased efficiency of digital business processes will decisively influence the success of a company in the next 18 to 24 months and beyond. You can download the complete Deloitte report aptly titled “Beyond the digital frontier”.

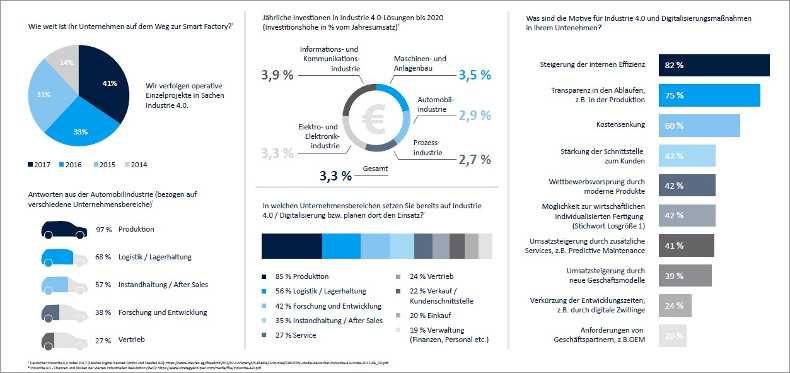

From the “fix when required” strategy to Smart Maintenance

Prior to the deployment of smart maintenance measures, the extensive use of machines and material, e.g. for maintaining and repairing the German railway network, turned out to be extremely time- and cost-intensive. True to the motto: “While we are at it…,” rails and switches were replaced even if this was not really necessary.

The times of this scattergun principle have long since passed, as even maintenance staff can no longer elude the mantra of high availability of Industry 4.0. The today’s magic word is: Smart Maintenance. This means predictive maintenance, repair and optimization. The objective: Time and cost reduction by minimizing unplanned downtimes./p>

In order for Smart Maintenance to function efficiently and in a recourses-saving manner, this industry sector increasingly relies on digitalization, big data mining and meticulous evaluation of data. Remote diagnosis and remote maintenance are also becoming more and more important and provide for optimum interaction.

You’ll find a status quo of the challenges in the field of maintenance and repair, more reading material and the interactive Quick Test: Where are you on your way to IIoT? on the website of Auvesy.

Industrial Cloud: What evolves if two industry giants cooperate?

Though Amazon with its web services generated “only” 11 percent of the group’s turnover of about 233 billion US dollars last year, in terms of profit it is quite a different story: impressively, 7.3 billion of the total 12.4 billion were produced by Amazon Web Services (AWS). This means that about 60 percent of the profit was realized by intangible cloud services, which a great number of industrial leaders such as GE, Siemens or Novartis rely on.

Volkswagen, one of the world’s greatest car makers, will also bank on AWS. The called target: VW wants to become more productive! The American trading group is to support Germany’s largest employer in bundling and networking the data of all machines, production facilities and systems from all the factories of the car manufacturer.

VW, in particular, counts on the Amazon technologies in the field of Internet of Things (IoT), Machine Learning and Computing Services that have specifically been developed for the industry of automobile manufacturing. This Industrial Cloud which is designed as an open platform and is expected to be in operation by the end of 2019 will be integrating about 30,000 locations of more than 1,500 suppliers in the medium to long run. VW considers this collaboration with Amazon as a long-term investment and a necessary pre-requisite for promptly providing all locations with new technologies and innovations. Learn more about the other objectives pursued by the car maker here.

Comment