Why The Right Coupling Matters In Heavy-Duty Hoist Applications

Cranes and hoists are only as good as their couplings, which are essential to maintaining uptime and enhancing the safety and reliability of your operation. Without the right coupling, your crane or hoist may not function properly, causing your manufacturing process to grind to a halt. This kind of downtime is not welcome – especially where very high loads and expensive equipment are concerned.

In the following we will focus specifically on hoists, briefly explore what these couplings are and the design features you should look for. There are two types of couplings that meet the demands for reliability and safety in crane and hoist applications.

Barrel Couplings – High Loads, Safe Handling

Hoists lift and lower loads using a drum or lift-wheel, around which a rope or chain wraps. Hoists can be manually operated, as well as electrically or pneumatically driven, and utilize chain, fiber or wire ropes as their lifting medium. From steel mills to manufacturing plants, hoists are used in wide range of applications that involve moving large, heavy products up and down.

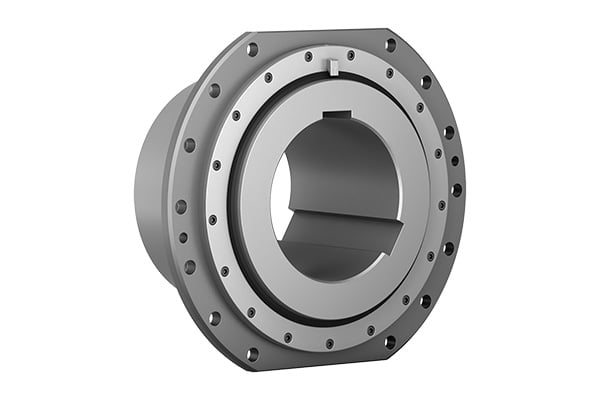

A well-proven coupling for hoists, barrel couplings connect the cable drum with the gearbox output shaft and are also used in winch conveyors and platform hoists.

These couplings transmit torque via barrel-shaped hardened pins that fit into semicircular, machined openings on the hub and sleeve – ensuring radial forces are transmitted safely.

Barrel couplings perform the function of an articulated joint, making the connection between the cable drum and gearbox statically determinate and avoiding high bending moments. They also allow angular and axial shaft misalignment caused by mounting inaccuracies, structural deformation and normal wear and tear. Without the flexibility provided by these couplings, the forces generated by the alternating bending loads can lead to shaft breakage and other costly, disruptive damages.

RINGFEDER® Barrel Couplings

Our barrel couplings (TNK series Barrel Coupling), which support the rope drum, can handle large amounts of torque, as well as heavy loads up to 815,000 Nm – making them reliable options for hoists with very high weight limits. Please see the other notable features on our website.

Gear Couplings - High Torque, Small Package

Another coupling typically found in hoists is the gear coupling, which connects the drive motor and gearbox. It can also connect the gearbox directly to smaller wire rope drums using a flanged half.

Gear couplings transmit torque via hubs with crowned gear teeth, which are in permanent mesh with the straight gear teeth of the sleeves – a design that provides the highest torque transmission for the smallest size. They also run at high speeds, conform to the AGMA bolting pattern and compensate for angular, radial and axial shaft misalignment.

Available in a variety of sizes, our gear couplings complement our extensive coupling offering for the crane and hoist market (RINGFEDER® TNZ ZCAK-ZCBK) – making your selection process easier than ever. Learn more about our barrel and gear couplings here.

Comment