Flange Couplings Beat Out Keyway-Based Couplings

Keyways aren’t the only way to couple heavy-duty motor and gearbox shafts. In fact, keyways aren’t even the best way when you consider the alignment and installation difficulties you’ll encounter when installing keyed shaft couplings that may weigh thousands of pounds. A better alternative is to use couplings that employ a mechanical shrink fit around the shafts.

How high? To take one recent example, we delivered a set of shrink disc Flange Couplings TNF that have a maximum rating of 325,000 Nm (240,000 ft-lb). These heavy-duty couplings, nine in all, join the motors and gearboxes that drive a big mining conveyor system. In this particular application, the couplings have to transmit reversing torques in excess of 244,000 Nm (180,000 ft-lb). No bending loads apply in this case, but these rigid couplings could have tolerated another 100,000 Nm (75,000 ft-lb) of bending forces in addition to the torque loads.

The shrink disc coupling (Flange Couplings TNF) beat out keyway-based couplings in this application for four reasons:

1. Eases Installation

Each one of the couplings weighs more than 780 kilograms (1,720 pounds). Trying to align and engage keyways with couplings this big is a job that the mine’s engineers wanted to avoid.

2. Disassembled Easily for Maintenance

The mine’s engineering team likewise wanted a coupling solution that could be disassembled easily for maintenance. With the shrink discs, loosening the locking screws releases the pressure on the flange hub. The connection returns to its original clearance fit dimensions, freeing the shaft for removal. Traditional machined shrink fits have no such release mechanism. To undo a traditional shrink fit, you have to heat the connection for hours to expand the coupling ID. Sometimes this procedure doesn’t go as planned, damaging the parts.

3. Resists Contamination

Once the locking screws are engaged and all the contact surfaces are under pressure, the shrink discs shut out dust and debris. This capability was important in a contamination-prone mining application.

4. Prevents Misalignment

Thanks to the even distribution of compression forces around the circumference of the shaft, shrink disc couplings inherently prevent misalignment.

In addition to use on mining and other large conveyers, flanged shaft couplings with shrink disc technology are also used in other heavy-duty applications—including gearboxes, process equipment, material handling systems and aggregate production.

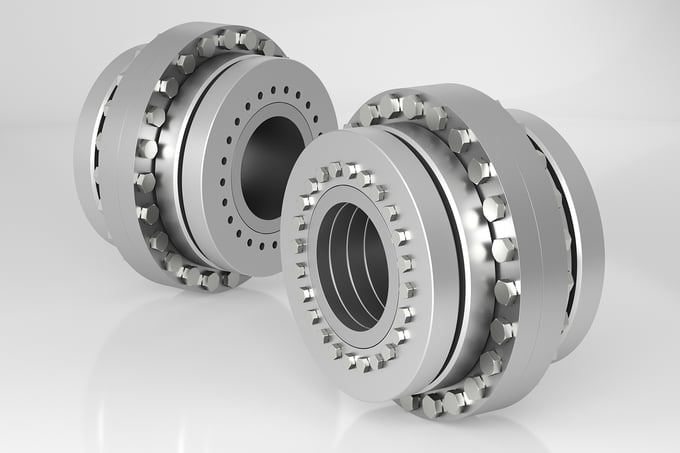

In our heavy-duty flange couplings, we use shrink disc technology to create that fit. To couple a hub and shaft, shrink discs use a system of tapered thrust rings, an inner pressure ring and a set of locking screws. When you tighten the locking screws around the circumference of the disc, the outer thrust rings are drawn together, compressing inner ring against the hub and the hub against the shaft. The resulting shrink fit can handle extremely high forces.

To learn more about our Flange Couplings for different applications, visit our website or send us contact request.

Comment