Highlights on Hannover Fair: Collaborative Robots and Boom in Automation

One of the highlights within the scope of the core topic "industry 4.0" was collaborative robots, as the new aid workers are called within the sector. This was not only a core topic but also an eye-catcher. While conventional robots are so far separated from the human work processes by safety fences, these collaborative robots shall work directly with humans and thus support workers in their activities.

Human Skills

The new generation of collaborative robots is scarcely inferior to man. They have amazing skills and also get increasingly more precisely, thus enabling a constantly improving cooperation between man and machine. BOSCH for example introduced the "APAS" assistant, a robot system which can detect movements of humans in its immediate surrounding, using built-in sensors, and immediately stop his movements before it comes to a direct contact and not, as most models do, just if a retarding force is detected.

KUKA already impressively demonstrated that robots have haptic skills and are capable to react on gestures in a video spot in 2014. It shows an exciting table tennis duel of man versus machine. This was enabled not only through improved drives and joints, but also through the integrated sensors and camera systems through which the robot could feel and see.

At this year's Hannover Fair many more robot assistance systems which can support humans in their work were presented than ever before. The Bionic Cobot presented by FESTO cannot only at a whim be bent into every required position, but beyond that, distinguishes through a pneumatic drive. It is therefore not dependent on an electric motor and thus ideally suited for the use in explosive environments. By means of pneumatics the joints of the robot system can be moved, the gripper can be initiated and through vacuum cups it is able to pick up workpieces, and with the new developed octopus-gripper can easily grip cylindrical objects.

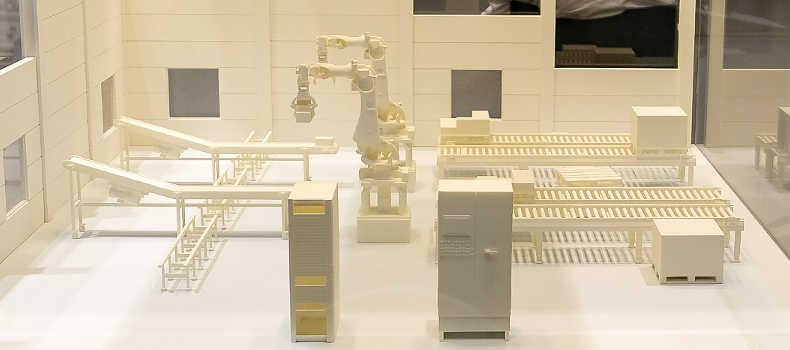

Automation model at the stand of RINGFEDER POWER TRANSMISSION

Automation model at the stand of RINGFEDER POWER TRANSMISSION

Increasing Demand in the industrial Automation

Integrating industrial robots into production flows is no longer just for the larger global player in the industry, but increasingly also for the smaller and medium enterprises worldwide. The automatized aides are offered at affordable prices; an example is the Lightweight-Cobot of Franka Emika. The Munich-based startup company has developed this mobile and sensitive robot arm and advertises that this system is building up itself – as first robot ever and at an acceptable price of 10.000 Euro.

On top of that specific requirements can be fulfilled, like the processing of new or very sensitive materials and high energy efficiency. And through specifically developed automation concepts the robots enable a link of the real production and the virtual world in terms of industry 4.0. Further on the usage at car production and metal processing sectors will be high, but also the aviation and the logistic sectors are increasingly using industrial robots.

That leads to a very large increase in demand in the rapidly growing branch of the robot manufacturers. The boom of the automation industry which started after the global economic crisis 2009 continues here. According to an IFR (International Federation of Robotics) estimate, by the end of 2019 more than one million new industry robots will be in service. At that experts assume, that globally each year about 13 percent more units will be employed.

The manufacturing industries of the European Union and also in Asia will take on a leading role here. South Korea, Singapore, Japan and Germany are the trailblazers. In Germany for example came 301 robots on 10.000 workplaces in 2016, compared to China with 49 units way back. But this is not meant to stay this way – experts predict that in two years time China will take around 40% of the globally produced industrial robots.

Robots as Aides

Collaborative robots, however, are not expected to make humans redundant but shall aid them. Dr. Jochen Köckler, member of the Managing Committee of the Deutsche Messe AG, speaks to this point: "The robot learns from the robot; but it is the human who tells him what tasks he has to carry out."

A good example for this is the Mars Rover "Curiosity". It is equipped with sensors to explore the surface of the red planet, however, it is controlled from Earth via radio signals, and also the analysis of the information gained there is done by the "team man" here. Thus we look to the future with optimism and we are excited about in which areas more the automatized colleagues will support us in the future.

Comment