Online Calculator Simplifies Locking Assembly Selection

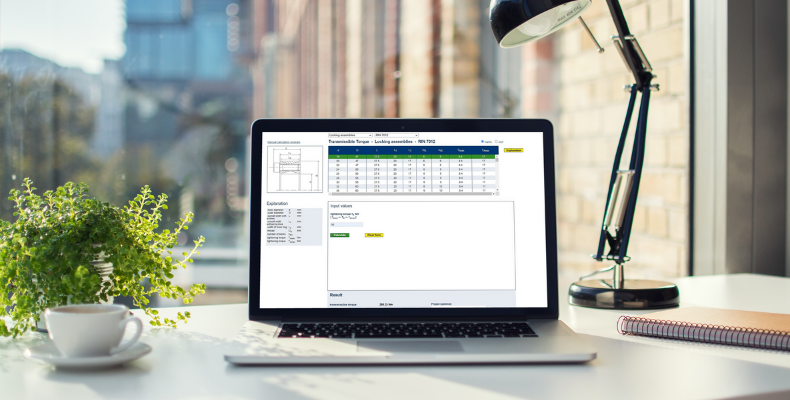

Locking assemblies and locking elements come in so many sizes and different technical features that it can be overwhelming to find the right one for your application. That’s why we have developed our online calculation tool that makes it easy to select the right product.

Locking assembly selection made easy

The online calculator evaluates your product selections based on your application requirements. The calculator works in three easy steps:

- First, select either a locking assembly or locking element and choose between a torque, hub or hollow shaft calculation.

- Next, enter torque and other application details like yield point, number of additional bores, hub dimension, coefficient of friction and screw size.

- Lastly, press calculate and you’ll get back useful engineering calculations such as maximum transmissible torque and minimum recommended hub outside diameter. You can save the analysis for later use or get all the details back in a PDF.

Discover the differences

The calculation tool can help you distinguish between some easily overlooked product differences. For instance, our RfN 7012 locking assembly features double-tapered thrust rings with self-releasing tapers which requires a pre-centering hub section since the RfN 7012 is not self-centering. They’re most commonly used in general engineering applications to transmit high torques and axial loads using larger machining tolerances.

On the other hand, our RfN 7013.0 locking assemblies are a single-taper design with a self-locking taper for good self-centering action and concentricity, as well as increased torque capacity. RfN 7013.0 locking assemblies don’t require a pre-centering hub section.

Comment