Selectively Compliant Coupling Protects Gearboxes

The big gearboxes that drive cable drums do not come cheap. Yet engineers often make a design mistake that can shorten the gearbox’s working life. This mistake involves the use of a rigid, direct coupling between the gearbox output shaft and the cable drum.

The problem with direct couplings boils down to statics: The rigid connection between the shaft and drum creates a statically indeterminate structure—one with too many

forces and not enough equilibrium equations. These structures can be subject to

unpredictable deformations and difficult to engineer properly. The usual strategy is to over-engineer and precisely align all the structural components. It’s a very expensive

strategy.

A better approach to cable drum mounting is to use a selectively compliant coupling

between the output shaft and the drum. The resulting structure will be statically

determinate, making it far easier to predict and manage the forces on the gearbox

output shaft.

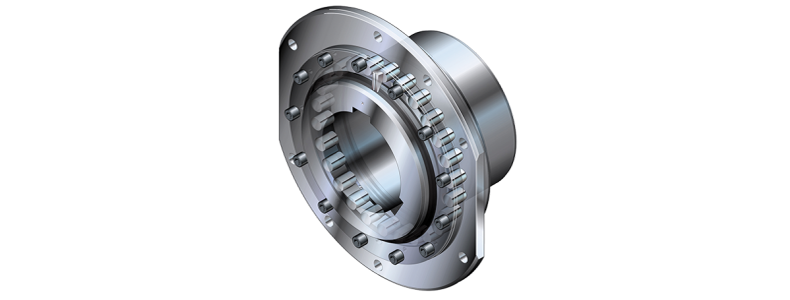

Barrel couplings, such as the TSCHAN TK models, are specifically designed for these

cable drum mounting applications—in cranes, hoists, winches and conveyors. These

couplings are selectively compliant in the sense that they can tolerate angular and axial misalignment without sacrificing the necessary torsional rigidity.

The TK barrel couplings consist of a hub, a sleeve and a collection of barrel- shaped inserts. Made from hardened steel, the barrel inserts transmit the torque as they roll

within mating semicircular pockets machined on the hub OD and the sleeve ID. The

barrel-shaped geometry of the inserts compensates for angular and axial misalignment between the hub and sleeve—and ultimately, between the gearbox shaft and drum.

Put differently, the coupling creates an articulating joint in the angular and axial directions while maintaining torsional rigidity. This articulating joint soaks up the

misalignments that occur as loads on the rotating drum change.

The barrel coupling hub attaches to the gearbox shaft, while the sleeve attaches to the

drum. The bulk of the coupling actually protrudes into the drum, giving the coupling a smaller overall profile than a comparable gear coupling. The entire coupling assembly is sealed to prevent any dust ingress. Because the coupling permits axial travel, the support bearing on the far end of the drum should be a self-adjusting bearing to

withstand axial loading.

TSCHAN TK barrel couplings are available with an outside diameter up to 850 mm and

can accommodate shafts up to 400 mm. Maximum torque is 650,000 Nm.

Comment