Friction Springs for Earthquake Protection of Critical Infrastructure Objects

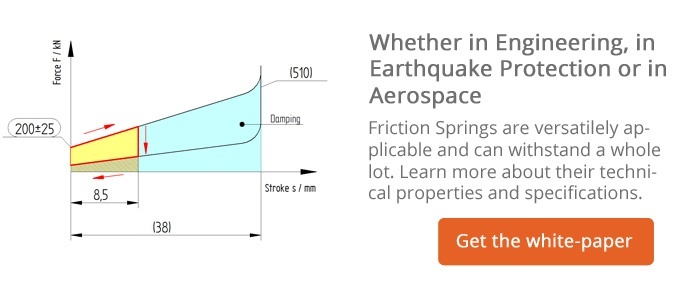

What started almost a century ago as buffer between railway cars has now become a universally applicable damping element for almost all industry sectors – also as a protective element against potential damages to buildings and industrial facilities caused by earthquakes.

The Beginnings in Earthquake Protection

The first Friction Spring application in the area of earthquake protection dates back more than 25 years: This was a "push-pull unit" for the protection of high-voltage switches. Initially, the application of RINGFEDER® Friction Springs for earthquake protection was limited to Utility sector – since 2007 they have been increasingly used for residential buildings with steel frames. Nevertheless, the main application field for RINGFEDER® Friction Springs in the area earthquake protection is still the utility sector.

Because it is very important that a power grid continues to function in the immediate aftermath of an earthquake. Due to the growing dependency of our society on computers and other electronic dependent systems, such as water supply, minimizing potential damages to transformer stations and the related equipment is critical.

The Project

On the initiative of Ringfeder Power Transmission, the first contact with the Seismic Engineering Team of SIEMENS AG Power Transmission Division was established a few years ago. Shortly after the initial meeting SIEMENS presented its design philosophy with view to securing their energy plants and equipment against damage caused by earthquakes. From this basic beginning it took several years until a suitable project came up:

In May 2016 Ringfeder received an inquiry for a preliminary specification for a project for an 800 kV high-voltage direct current transmission line (HVDC) in China.

The high-voltage transmission line between the stations Xinsong (province Yunnan) and Dongfang (province Guangdong), which supplies the industrially developed greater area of Guangzhou with power, is operated by the electricity company China Southern and has a total length of 1.923 km.

The Requirement

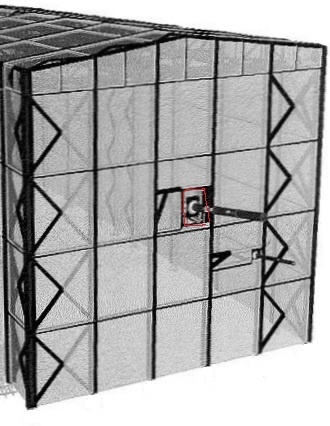

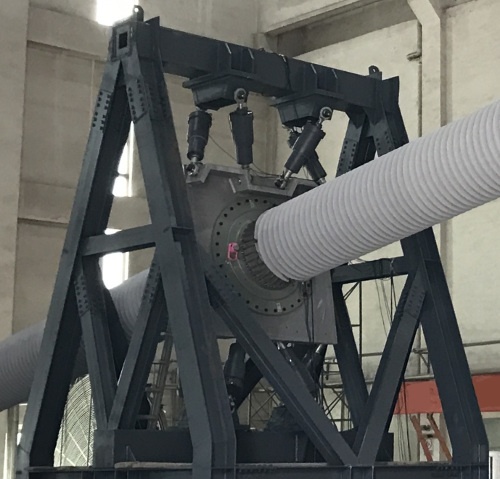

The imposed requirement was to hang a wall bushing in an earthquake proof manner in a steel frame which is integrated into the building wall:

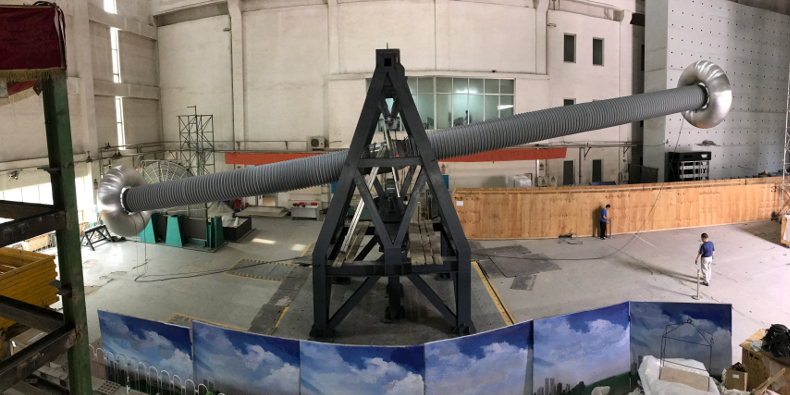

The wall bushing (length appr. 20 m, weight appr. 10 t) is flexibly connected to the steel frame via a centrically mounted steel plate by the help of RINGFEDER® push-pull units. It is led from inside the hall, where the transformer is located, under a defined angle to the outside. Its function is to transport the direct current from the outside to the inside of the valve hall, where the converter valves are located.

The Solution – RINGFEDER® Push-Pull Damper

The push-pull units had to be designed in such a way, that firstly they hold the dead weight of the wall bushing and, secondly, do not react even under strong wind loads. Frame and wall bushing are designed to be so stiff that the energy absorption is not done through a deformation of these components but imposed by the dampers.

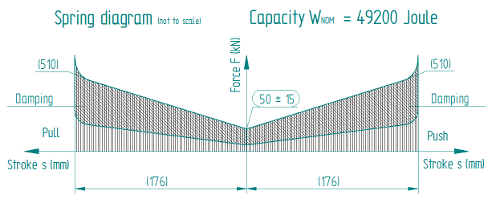

Initially it was planned to use a 20000 spring-type push-pull unit with a capacity of 50,000 Joules at 66% damping, which was designed to absorb the forces and energy generated during an earthquake event.

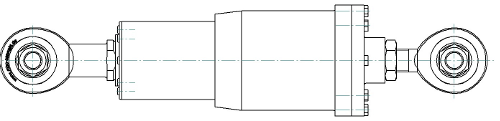

Initial design of the damper

Initial design of the damper

Additionally, maintaining a given spring stiffness to ensure the above-described process of energy absorption through the dampers as well as a connection to the steel frame, which allows an angular misalignment between the damper and the wall bushing needed to be ensured.

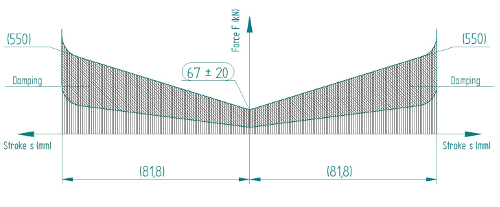

After several iterations, the requirements respective the designed dampers were optimized such that instead initially requiring 10 units only 8 units were needed, and instead of the original single spring type 20000 a smaller double spring consisting of types 16600 and 12400 was used:

Final design of the damper

Final design of the damper

As a result, the required installation space was reduced. The push-pull damper, which has specifically been designed for this application, has a total length of 932 mm at a weight of 145 kg.

RINGFEDER® push-pull damper type 16600

RINGFEDER® push-pull damper type 16600

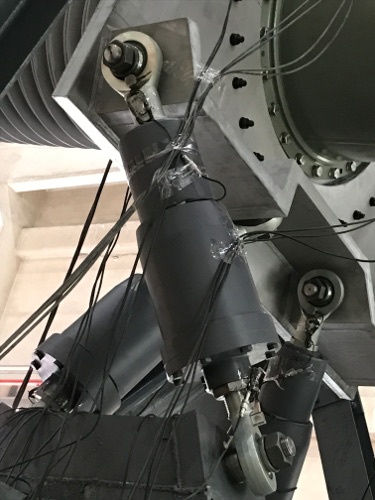

The connection of the units was realized by using joint heads which can accommodate a bolt diameter of 70 mm. Upon completion of the dampers they were sent to Beijing for testing in April 2017.

RINGFEDER® push-pull damper type 16600

RINGFEDER® push-pull damper type 16600

Test Successfully Passed

The on-site test was supervised by SIEMENS in cooperation with an application engineer of RINGFEDER. During the test a magnitude 0.4 g earthquake was simulated. After the test the intactness of the mechanical construction was verified.

Wall Bushing

Wall Bushing

An electrical and mechanical test of the wall bushing made before and after the test ensured that its function was not impaired by the test and that all components work flawlessly. Accordingly, the test was successfully passed and the adequate earthquake protection through the use of RINGFEDER® Friction Springs proven.

More information on friction springs for earthquake protection.

Comment